At SFVEST, our quality control covers the entire process from raw material procurement to product shipment, ensuring each item meets the highest standards. We carefully select suppliers and conduct physical and chemical tests on all incoming materials; only certified materials are used in production. During production, we implement real-time monitoring and periodic checks, with dedicated personnel supervising and recording key quality metrics. Advanced automation reduces human error, ensuring consistency and reliability.

At SFVEST, our quality control process spans from the procurement of raw materials to the final shipment of products, ensuring each item meets the highest standards.

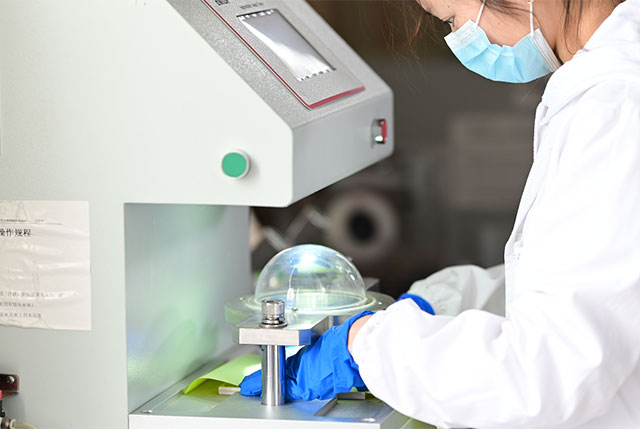

Raw Material Procurement and Incoming Inspection:

We carefully select suppliers and conduct stringent incoming inspections of all raw materials. Upon arrival, our quality control team performs physical and chemical property tests to ensure the quality of materials meets our strict standards. Only certified materials are allowed onto the production line.

Production Process Control:

During production, we implement real-time monitoring and periodic checks to oversee the quality of manufacturing. Each production step is manned by dedicated quality control personnel who supervise and record key quality metrics throughout the manufacturing process. Additionally, we utilize advanced automation equipment to minimize human error, ensuring consistency and reliability in our products.

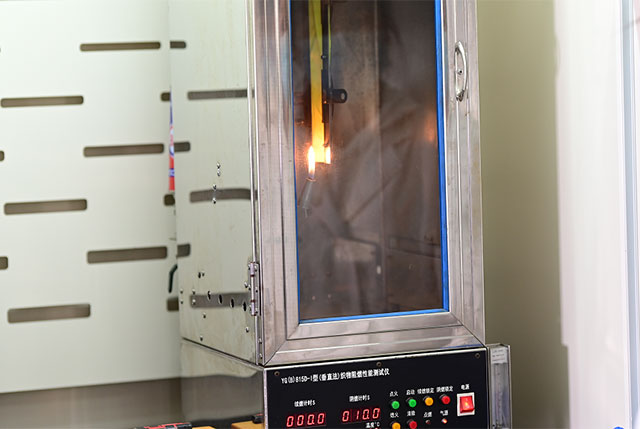

Final Product Inspection and Testing:

After production, each batch of products undergoes rigorous final inspections. This includes visual inspections, dimensional measurements, functionality tests, and durability tests to ensure each product is defect-free and complies with technical specifications. Moreover, random sampling is conducted to assess the overall quality of the production batch.

Packaging and Shipping:

Products that pass the final inspection are appropriately packaged to protect them during transportation. Our logistics team ensures all product packaging meets domestic and international transport standards and monitors the shipment status through tracking systems until safely delivered to customers.

Through this comprehensive set of quality control measures, SFVEST is committed to ensuring that every shipped product meets or exceeds customer expectations.